POOSHESH

A FITTING CASE FOR EVERY PRODUCT

Pooshesh offers a vast selection of plastic casings in terms of caliber range, layers, thickness and printing. Our products come with an excellent consistency in properties using a perfect combination of different high-performance Polyamides supplied from word’s top brands to provide and guarantee a unique level of performance to our customers. The superior mechanical properties of our plastic casings, makes it an excellent choice for sausage production. Our casings are used for a wide range of sausage products including cooked, uncooked, smoked and unsmoked sausages. We also offer Easy Peel casing for automatic peeling machines and for sliced sausages. To learn about technical features of all products please see PRODUCTS menu.

Plastic Sausage Casings

Our casings are used for a wide range of meat sausages and also for dairy products. Primary materials for production line are supplied from world class European suppliers including polyamide, masterbatch, adhesive and printing ink in compliance with highest standards for food contact products. Benefiting from the equipment developed for Pooshesh Tehran Navid Co. in Germany and Switzerland, the latest technology of polymer extrusion has been applied in manufacturing sausage casings. All of our products passed industrial toxicological tests, heavy metal content, GMO and allergens tests with excellence. We have ISO, HALAL, CE and HACCP certificate.

Monolayer and Multilayer Casings

Applying solo extruder or several extruders in production line, we offer both monolayer and multilayer casings for different applications. In order to provide prolonged shelf life for sausages and to enhance seal factor of the casings to avoid weight loss, also to keep quality of the final products at optimum levels, we offer multilayer plastic casings. Regular shelf life provided by monolayer casings are 3 weeks and for multilayer casings extends to 6 weeks. Of course storage condition must be considered to achieve prolonged shelf life.

Permeable and barrier Casings

Beside barrier casings used for unsmoked products, smoke permeable casings are also offered for smoked meat and cheese products. Permeable casings are monolayer to enhance the penetration of smoke through the casing. Smoking is done in smoke chamber in specific conditions of temperature, pressure and humidity. Smoking time is different for different products with the average of 2 hours. The perfect smoke taste is achieved using special wood chips.

Biaxially orientated casings

Orientation makes the casings stronger and more stable through alignments of its polymer chains to acquire better properties. Being biaxially oriented gives the casings benefit of enhanced mechanical and barrier properties. The shrinkage force built up in the casing structure will be released during sausage making procedure and exposure to heat. This feature adds up to the adhesion quality between meat and the casing as well as avoiding wrinkle formation on the product.

Perfect Stuffing

By nature, our casings must be stuffed to the recommended diameters. If the over-stuffing is not done properly, then there will be wrinkles on final product. General expansion is about 10% for all products; however it could vary based on machinery and emulsion specifications. Choosing correct size of filling horn which is just little bit smaller than interior diameter of the casing is necessary for stuffing.

Soaking

Our mini-calibers don’t require soaking before stuffing. However some consumers prefer to soak them before use. Big calibers require soaking properly before application in 28 °C water for about 1 hour to allow the casing to absorb water adequately. Both interior and exterior surface of the casing must be exposed to water for an effective soaking. Improper stuffing or breakage during stuffing and cooking will occur in case of improper soaking.

THE COMPANY WITH A PASSION FOR CASINGS®

Clipping

Closure can be done using appropriate clipping and tying methods. Aluminum clips are very popular. Choosing the right clip size is important. Applying a too big clip will lead to slippage and wrinkles on the products. On the other hand applying a too small clip will cause cut and breakage of the casings during filling and processing. Clipping can be done using automatic clippers or manually. Twisting is a replacement for clipping. This method is popular in many markets and applied widely.Cooking

Cooking position can be both horizontal and vertical. For different products based on their weight and emulsion, cooking time and temperature varies. Average cooking time could be from 1 hour for small sausages to 3 hours for big calibers. Cooking temperature must be set to achieve desired core temperature depending on product weight and emulsion. Normally, the cooking temperature is set to 80°C. The core temperature of 72°C should be reached during cooking.Cooling

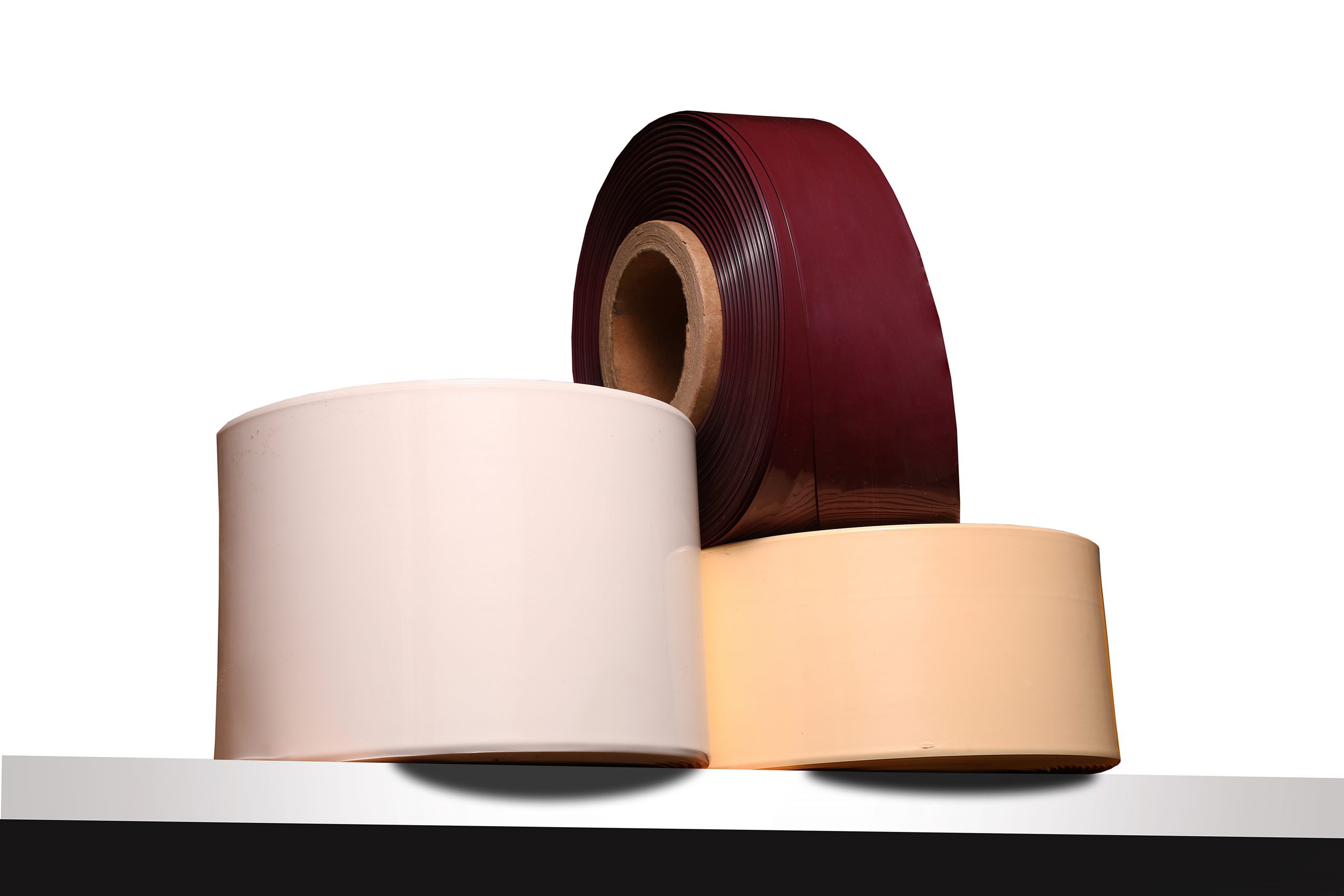

Cooling down is done without the risk of bursting, applying common usual ways. The only consideration is to avoid fast cooling with high airflow or iced water. For a perfect result, following measures can be taken (optional): Right after cooking let the sausages rest in room temperature for about 12 hours; Cold showering; Transfer the sausages into cooling room and let them rest to reach a core temperature of 4°C. The long cooling time is to reach desired cohesion and consistency in sausage texture to get nice slices of final product.Casing colors

One of the advantages of using plastic casing is to benefit from the option of unlimited colors! Pooshesh offers casings in variety of unlimited colors from beautiful shiny colors to tint and clear casing. All pigments used for production of colored casings comply with standards and regulations for materials that come in contact with food with accredited health certifications. We color-match our casings to your specific color requirement.Printing

All products are offered with the option of multi-color printing on one or both sides of the casings. For mini-calibers we do 6+6 and for big calibers we do 8+8. Picture designs are also beautifully printed on big calibers with high-quality flexo printing. Our graphic designers in printing plant are in regular contact with our clients in order to bring new creative ideas to their art works. By producing exclusive designs for our customers, we help them to make a perfect presentation of their products in the market.Reels and shirred sticks

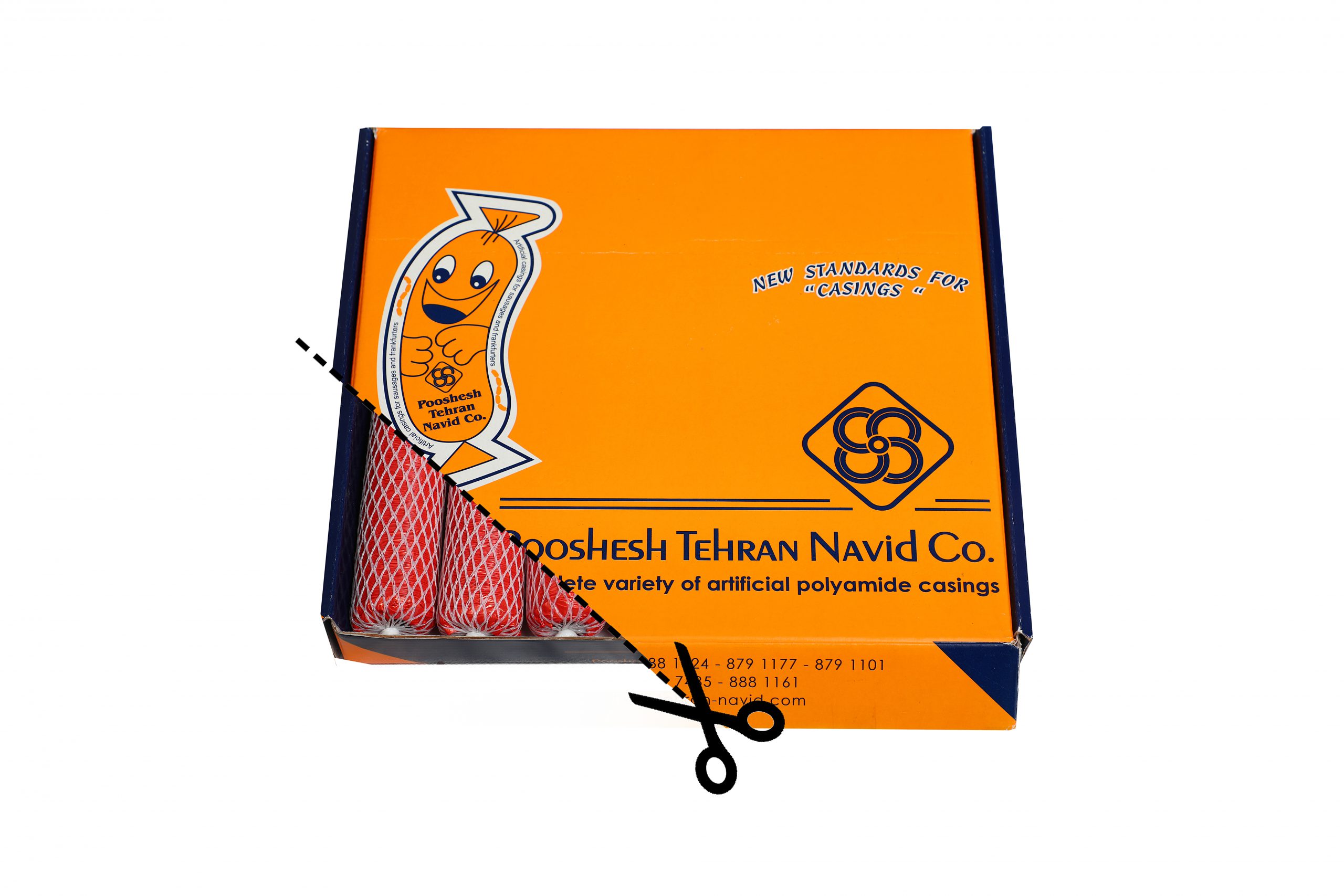

Mini-calibers are offered in shirred sticks and big calibers are available in reels and shirred sticks. Length of shirred sticks can be adjusted upon request. Shirred sticks are available in open and closed ends. Shirred sticks are wrapped in nets for more protection. One important benefit of using shirred casing over reels is convenience for proper soaking which is very helpful for big calibers.Storage time and conditions

Storage time of 24 months is suggested for all casing types under optimum conditions characterized as cool and dry place protected from frost (4°C to 30°C), keeping in original sealed packaging until ready to use, un-used casings must be kept in airtight plastic bags to maintain moisture content.

Minimum weight loss

One of the advantages of using plastic casing over other natural or artificial casings such as fibrous and cellulose casing is the issue of weight loss. During sausage processing, high heat causes evaporation of water and therefore weight loss of final products. High barrier features of our plastic casings prevent any weight loss during thermal process and cooling. Weight loss for our casings is almost zero.

EASY PEEL Casing

EASY PEEL casing provides optimum sausage release from casing due to the characteristics of special plastic resins used in its production which prevents formation of strong bonds between meat and the casing. This quality makes EASY PEEL casing an excellent choice for sliced, canned or vacuumed products. This casing is suitable for manual or high speed automatic peeling machines. EASY PEEL is recommended in light or semitransparent colors to make any unpeeled casing parts visible.

Ring-shaped casings

We are proudly the first and the only producer of Ring-shaped casings in Iran. The technology was developed in our factory with the hard work of our technicians and experts using 100% domestic resources. This type of casing is available is caliber 32, 36 and 38 and specific colors. Because of unique technology in our factory and so many demands from domestic clients, this line is mostly dedicated to domestic clients and fully booked almost all year round.

Thermal resistance

Our plastic casings benefit from high thermal resistance coming from special plastic resins used in their structure. This feature is very important and useful is some procedures required in food manufacturing such as freezing and sterilization. Our casings can be used for frozen products as well as pasteurized and sterilized products meaning temperature ranging from -20°C to +121°C can be tolerated.

Water-vapor and oxygen transmission rate

Testing our casings in specific temperature and relative humidity conditions shows the lowest levels of transmission rate for oxygen and water vapor in compliance with ASTM E-398, ASTM D-1653 and ASTM D-3985. Because of such properties, the weight loss of products during processing and storage is minimum. *values depend on temperature, casing material, thickness and pressure

Packaging and Labelling

We have a practical and protective packaging system designed for all types of our products. Our packaging protects the casings and keeps the moisture at optimum levels during transportation to final destination. Our packaging protects the specifications of the products during long storage times. For our esteemed customers all around the world, we provide the option of putting specified labels on the boxes with every detail required in their own language.